Technical Circular No: 038/2023

1. MARPOL Annex I, Regulation 14 requires an Oily water separator (OWS), bilge separator or oil filtering equipment to be installed on any ship of 400 GT and above. The Oily water separator (OWS), bilge separator or oil filtering equipment is to be approved by the Administration and is to be installed in accordance with the guidelines contained in IMO Res. MEPC.107(49) as amended by IMO Res. MEPC.285(70).

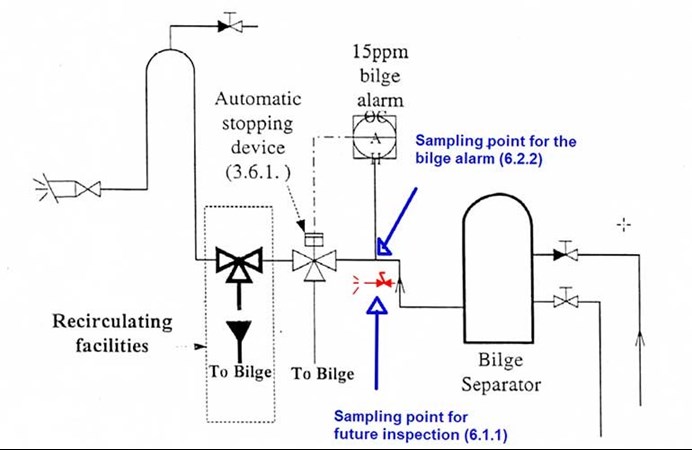

2. The IMO Res. MEPC.107(49) requires following sampling points to be installed as under:

(i) Sampling points for future inspection (paragraph 6.1.1):

Paragraph 6.1.1 of IMO Res. MEPC.107(49) requires -

“For future inspection purposes on board ship, a sampling point should be provided in a vertical section of the water effluent piping as close as is practicable to the 15ppm Bilge Separator outlet”.

(ii) Sampling points for the bilge alarm (paragraph 6.2.2):

Paragraph 6.2.2 of IMO Res. MEPC. 107(49) requires -

“The arrangement on board ship for the extraction of samples from the 15 ppm Bilge Separator discharge line to the 15 ppm Bilge Alarm should give a truly representative sample of the effluent with an adequate pressure and flow” i.e. sampling point for extracting samples to the bilge alarm”.

3. Thus it can be seen from above that item (i) requires sampling pint to be installed in a vertical section of the effluent pipe applies to the sampling point for inspection only and does not apply to the sampling point for extracting samples to the bilge alarm as mentioned above at item (ii). For sampling point as mentioned under item (ii) above, the applicable installation requirements by the manufacturer of the oily water separator / bilge separator are to be followed to ensure a representative sample of the effluent with adequate pressure and flow.

4. Possible locations of these two sampling points are shown below as adapted from Figure 1 of IMO Res. MEPC.107(49). A loop may be installed at the bilge separator outlet to comply with the requirement stating that the sampling point for inspection purposes should be a vertical section of the effluent pipe.

5. The requirement contained in IMO Res. MEPC.107(49) to install the sampling point on a vertical section of the effluent pipe has recently been the focus during port state control inspections.

6. Shipowners, Managers/Operators of our classed ships are requested to review the above information provided and ensure that the OWS sampling points are installed in a manner as explained above.

Enclosure:

Disclaimer:

This Technical Circular and the material contained in it is provided only for the purpose of supplying current information to the reader and not as an advice to be relied upon by any person. While we have taken utmost care to be as factual as possible, readers/ users are advised to verify the exact text and content of the Regulation from the original source/ issuing Authority.

Download PDF

Download PDF