Metallurgical Tests

We are able to provide the following metallurgical tests :

- Macrostructure Analysis

- Microstructure Analysis

- Grain Size

- Case depth

- Determination of delta ferrite content

- Sensitization tests on welds

- Inclusion rating

- Decarb depth

- Coating/ plating thickness

- IGC test

- Corrosion test

- Thin surface hardened steel

- Micro crack density

- Mass of Zn, Phosphate coatings

- Evaluation of weld Joints - butt joint, fillet joint, hard facing, friction welds, stud welds, spot welds, projection welds and brazed joints

- Evaluation of quality of weld and calculating % depth of penetration

- Evaluation of Sensitization at welded regions of ferritic stainless steels

- Detection of Detrimental intermetallic Phases by Method A and C in Duplex Stainless Steel

- Intergranular Attack in Ferritic Steel Practice W Practice Z in Duplex Stainless Steel

- Pitting Corrosion Test Method A Method C Method E

- Crevice Corrosion Test Method B Method D Method F

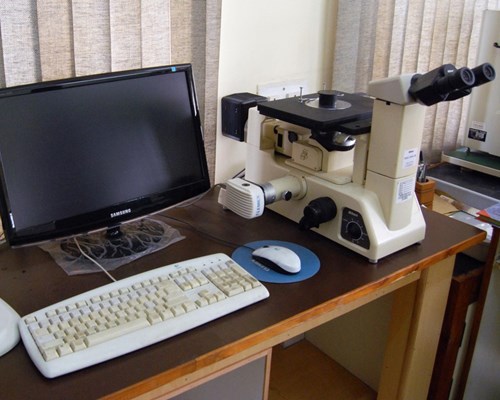

Metallurgy Lab

Sample Preparation Equipment

Optical Microscope with Chennai Metco Image Analyzer

Stereo Zoom Microscope